Researchers at the University of Tsukuba create a new method to fabricate finger prostheses with 3D printing technology.

Finger amputation is the most common amputation of the limbs. However, prostheses for patients with finger amputation are frequently excluded from the support of social and welfare programs.

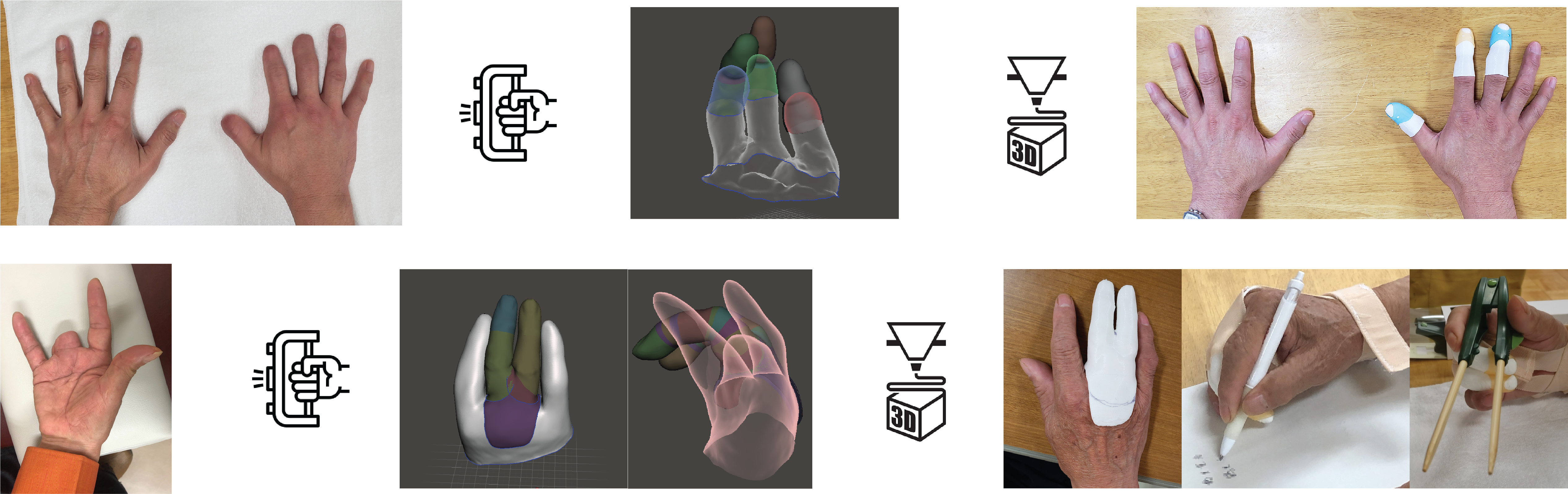

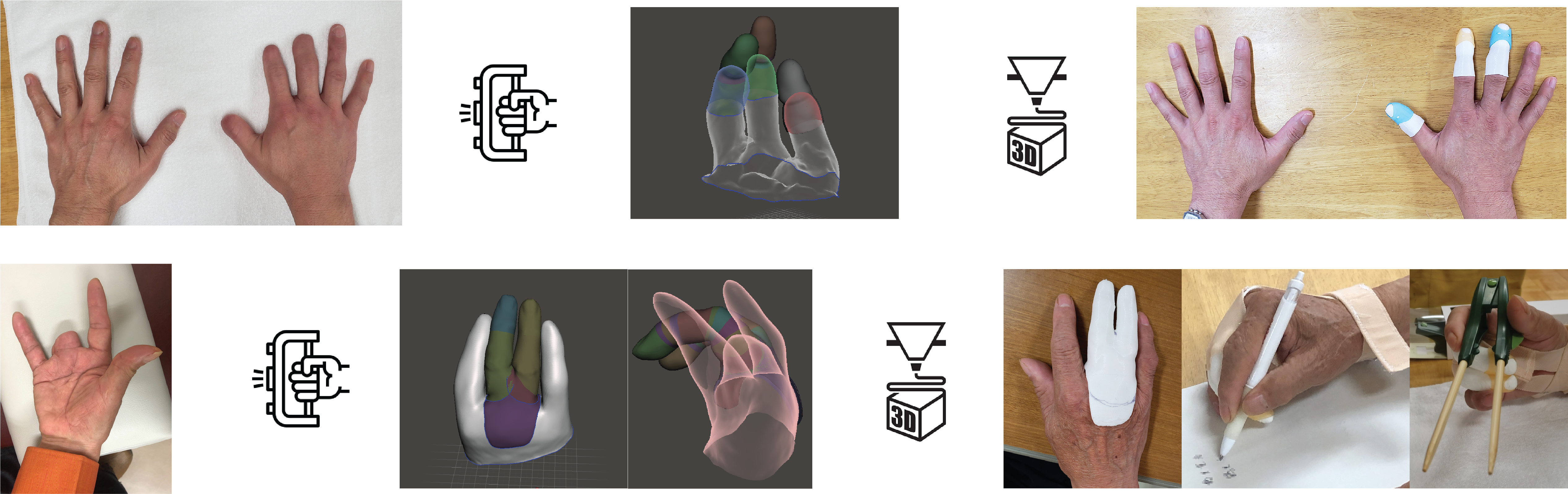

Researchers at the University of Tsukuba and the University of Tsukuba Hospital address this issue by fabricating finger prostheses with consumer-level digital fabrication tools such as desktop 3D scanners and 3D printers. The method they devised enables the creation of prostheses that match the shape and contour of the recipient’s remaining fingers and limb with very low cost and a very short waiting time.

Passive finger prostheses have been mainly used for aesthetic appearance, and to improve the social lives of persons with finger amputation. The fabrication method devised by the researchers adds functional advantages to passive finger prostheses owing to two unique properties: one is that the finger joints and posture can be adjusted at the design stage to fit different tasks, such as holding a pen, chopsticks, or typing on a keyboard. And the other is that the fingers are fabricated with soft fingertips similar to biological fingers, which allows good grasp on objects, and good interaction with the physical surroundings.

The researchers tested the method by designing and printing prostheses for two recipients at the University of Tsukuba Hospital, Department of rehabilitation. Both the recipient’s acquired finger prostheses that fit their hands and are suitable for conducting a variety of daily life tasks.

This work is published in IEEE ACCESS as “Rapid and Flexible 3D Printed Finger Prostheses With Soft Fingertips: Technique and Clinical Application” (10.1109/ACCESS.2022.3181140), and was featured on the top page of IEEE ACCESS.

Funding

This work was supported by the Japan Society for the Promotion of Science Grants-in-Aid for Scientific Research (KAKENHI) under Grant 18K10740 and Grant 21H03475.

Journal

IEEE ACCESS (open access journal)

DOI

10.1109/ACCESS.2022.3181140

Article Title

Rapid and Flexible 3D Printed Finger Prostheses With Soft Fingertips: Technique and Clinical Application (Peer-Reviewed Publication)

Publication Date

08-June-2022

Correspondence

Assistant Professor HASSAN Modar

Faculty of Engineering, Information and Systems, University of Tsukuba

Researchers at the University of Tsukuba create a new method to fabricate finger prostheses with 3D printing technology.

Finger amputation is the most common amputation of the limbs. However, prostheses for patients with finger amputation are frequently excluded from the support of social and welfare programs.

Researchers at the University of Tsukuba and the University of Tsukuba Hospital address this issue by fabricating finger prostheses with consumer-level digital fabrication tools such as desktop 3D scanners and 3D printers. The method they devised enables the creation of prostheses that match the shape and contour of the recipient’s remaining fingers and limb with very low cost and a very short waiting time.

Passive finger prostheses have been mainly used for aesthetic appearance, and to improve the social lives of persons with finger amputation. The fabrication method devised by the researchers adds functional advantages to passive finger prostheses owing to two unique properties: one is that the finger joints and posture can be adjusted at the design stage to fit different tasks, such as holding a pen, chopsticks, or typing on a keyboard. And the other is that the fingers are fabricated with soft fingertips similar to biological fingers, which allows good grasp on objects, and good interaction with the physical surroundings.

The researchers tested the method by designing and printing prostheses for two recipients at the University of Tsukuba Hospital, Department of rehabilitation. Both the recipient’s acquired finger prostheses that fit their hands and are suitable for conducting a variety of daily life tasks.

This work is published in IEEE ACCESS as “Rapid and Flexible 3D Printed Finger Prostheses With Soft Fingertips: Technique and Clinical Application” (10.1109/ACCESS.2022.3181140), and was featured on the top page of IEEE ACCESS.

Funding

This work was supported by the Japan Society for the Promotion of Science Grants-in-Aid for Scientific Research (KAKENHI) under Grant 18K10740 and Grant 21H03475.

Journal

IEEE ACCESS (open access journal)

DOI

10.1109/ACCESS.2022.3181140

Article Title

Rapid and Flexible 3D Printed Finger Prostheses With Soft Fingertips: Technique and Clinical Application (Peer-Reviewed Publication)

Publication Date

08-June-2022

Correspondence

Assistant Professor HASSAN Modar

Faculty of Engineering, Information and Systems, University of Tsukuba